Kindly read this guide before assembling.

PCB Testing

Test your PCB first before soldering. Check every pin with a tweezer.

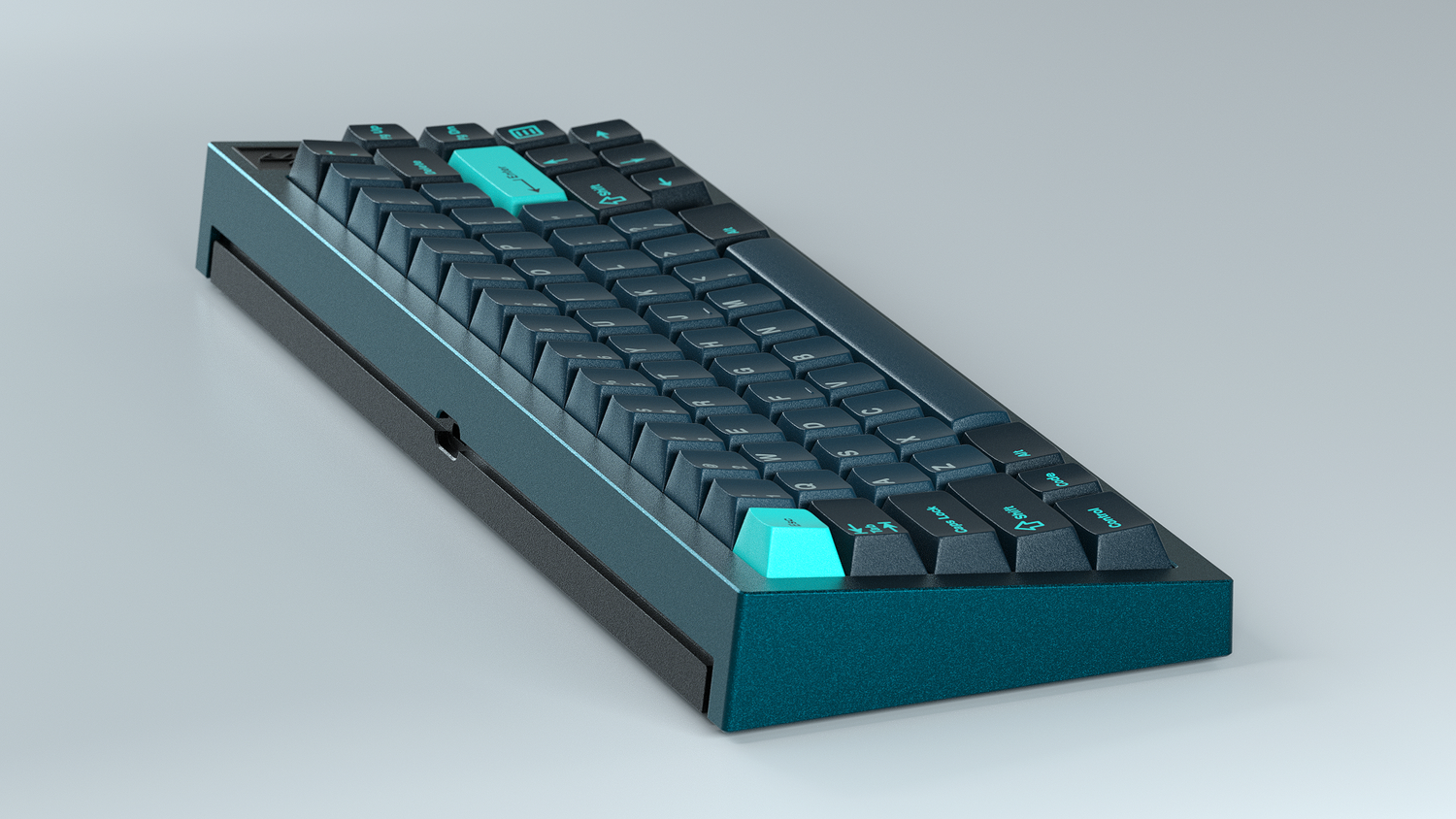

Keyboard Case Build

Here are a few tips that could help with screws overtighten issues.

1. Make sure you are using the correct tool, we used an S2 Allen key.

Wrong tools may cause damage to the screw head. It is not recommended to use the Torx type for these screws, it has a higher chance to strip the screw head.

Please use the S2 Allen key(circled in red on the below pic) to take out screws for the iron165 keyboard case.

If you feel some screws are a bit tightened, make sure you hold the screwdriver tightly, press with a bit of force, and turn the screwdriver slowly.

We won’t be able to process an exchange if the screws are damaged, as there is no way for us to take them out. Contact us if you are facing any issues.

2. When you find that the screw is tight and it is difficult to take it out even with a lot of force, please stop to avoid damaging the screw head. At this point, you need to apply a little bit of WD40 into the screw hole and wait 40-60 seconds for the WD40 to penetrate the screw hole. Sometimes it can be up to 24-48 hours, depending on the situations.

After that, you can try to twist the screw up and down in small increments, and repeatedly. After that, you should be able to remove the screw.

How to clean WD40 after usage?

Use a clean cotton swab to absorb WD40 in the screw holes.

Apply some water to a clean tissue/cloth and wipe the keyboard surface gently.

Watch this video for easier understanding!

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.